Our Solutions

Click on each solution to explore various ways we can be of service to your business

Click on each solution to explore various ways we can be of service to your business

PRODUCTION FLOW ASSURANCE

Low dosage & high efficiency flow assurance solutions

A Broad-spectrum Biocide, BG - Biocide

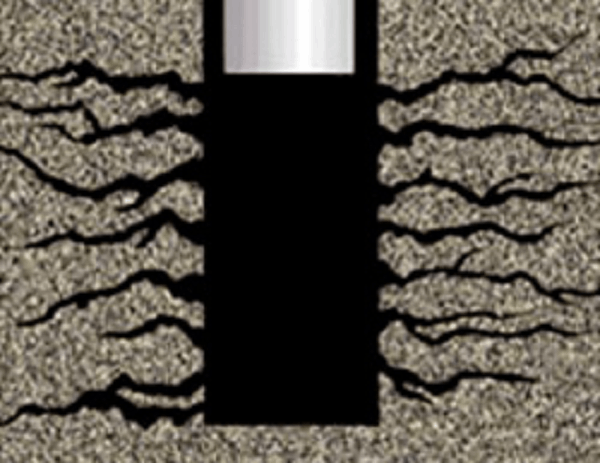

DEEP MATRIX STIMULATION - without HCl

Using the effective BG-STM Solution, a corrosion inhibitor

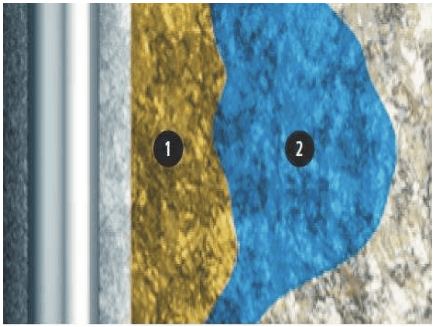

1

– Conventional Acid Penetration Depth

2

– BG-STM Penetration Depth

BG-STM Advantage

BG-STM overcomes drawbacks of using HCl such as:

REMOVAL OF PARAFFIN WAX DEPOSITS IN WELLS & PIPELINES

BG-EXO – THERMOCHEMICAL SOLUTION

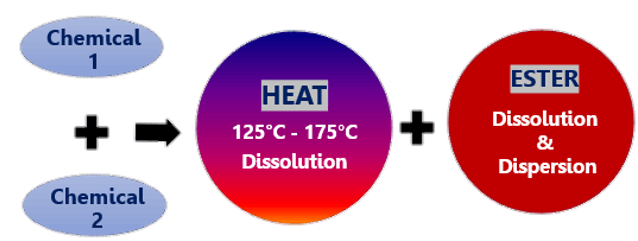

BG-EXO is a unique thermochemical system consisting of two chemical

pills

which are injected simultaneously into the targeted location.

Chemicals can be bullheaded to the target location

The resultant reaction will generate in- situ heat of between 125ºC to 175ºC and an

Ester.

Combining the effect of thermal energy and chemical solvency has proven to be

highly

effective in dissolving, dislodging, dispersing and removing the organic solid

wax deposits.

The crude requires no additional treatment on surface.

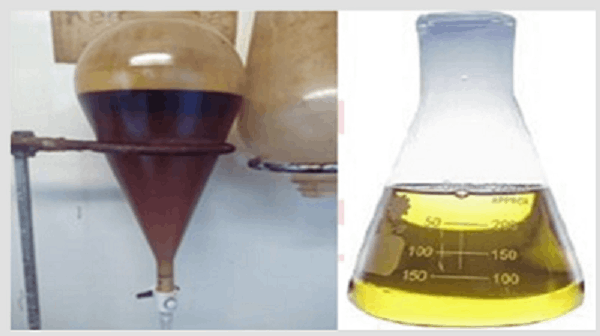

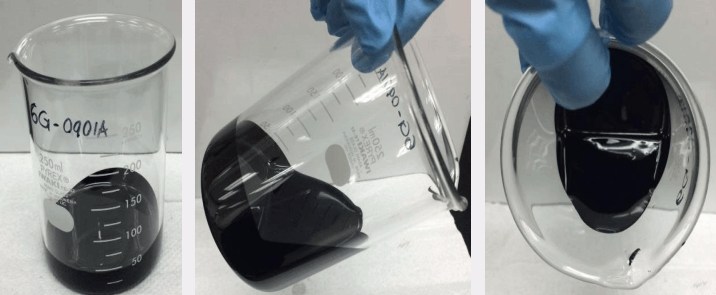

The Resultant Ester Solution

Benefits

SCALE PRECIPITATION & DEPOSITION

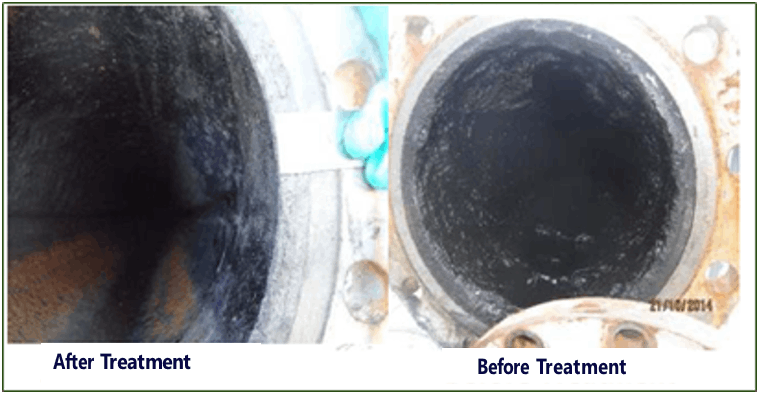

Effective De-Scaling of Wells and Pipelines using BG-CLENZ

BG-CLENZ - A specially formulated single pack treatment designed

to remove deposits in the flowline, wellbore, sandface and reservoir.

It dissolves and disperses both organic and inorganic deposits

without any heating or mechanical agitation.

BG-CLENZ Advantage

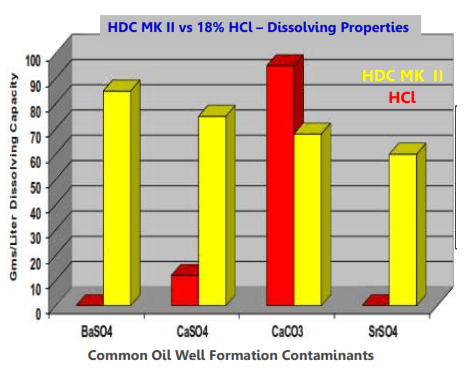

REMOVAL OF BARIUM SULPHATE SCALES IN OIL WELLS USING HDC MK II

HDC MK II completely dissolves Barium Sulphate and opens the hydrocarbon flow path

BaSO₄ Removal Challenge

Features of HDC Mk II

The Reaction

CASE STUDY - Barite Damaged Well

Background

Result/Benefits

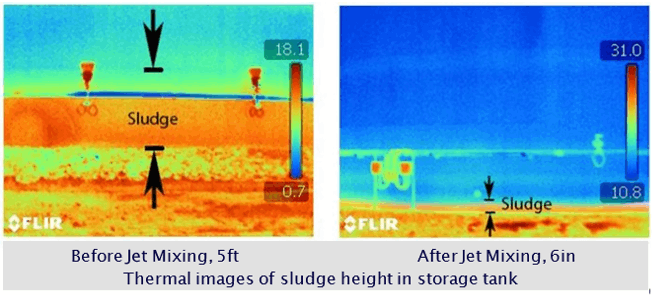

SLUDGE REMOVAL & PREVENTION

Tank mounted In-line Jet-mixer for Sludge Removal & Prevention

In-line Jet Mixing facilitates man-less cleaning of the storage tank with the introduction of high velocity fluid jets into the crude oil tank for the purpose of shearing the paraffin and re-suspending the accumulated sludge.

The Jet Mixing System can enable you to -

FEATURES & BENEFITS

ENHANCING HEAVY CRUDE OIL PRODUCTION

Improve flowability of heavy crude – enhancing production, transport & storage using BG-VRL /

BG-VRX / BG-PB

Production & Transport of Heavy Crude challenging due to:

Features & Benefits

PRODUCED WATER TREATMENT

Separation of suspended solids and dispersed oil from produced water.

Two solutions

PATENTED LIQUID SOLUTION, DEOILER

Deoiler, accelerates oil-water separation in hydrocyclone.

Applications:

Features & Benefits

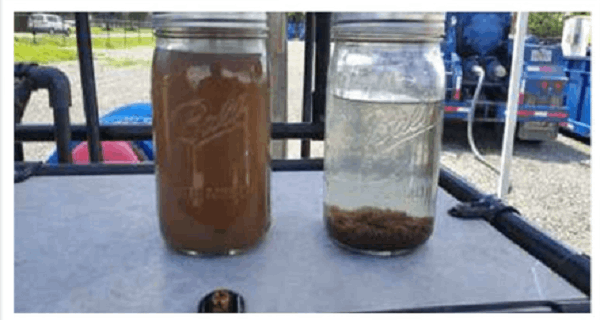

COMPACT MOBILE TREATMENT PLANT, MTP

The MTP is a novel water treatment technology where waste is removed using nano polymer dispersion.

The system can treat and clarify produced water and leave sub-2ppm treated water.

Features & Benefits

BIOREMEDIATION SOLUTION

Breakdown and degrade hydrocarbons in oil spill site using anaerobic microorganism

Bioremediation is a commonly used technique for the cleanup of oil spills. It involves the use of microorganisms to break down and degrade the hydrocarbon compounds present in the spilled oil.

Features & Benefits